LEATHER TANNING

Documentation of Indigenous Practices

A documentation of Indigenous practices in India. This is a documentation of natural leather tanning which is practiced by Dhor community in Nippani, Karnataka.

Mahalaxmi Temple

Kolhapur is known as a holy city. Abode of Mahalaxmi, this city has many ancient temples. Among the 108 shakti peths which are listed in the ancient scripts, Kolhapur’s Mahalaxmi temple is one.

Pravasi Vitthal

This temple is built in 12th Century BC and has a very unique story that goes back to the Kolhapuri Chappals. This temple is located in old Kolhapur. It is very rare to see Lord Vitthal with Rahi and Rukhmini both together.

Also locals call it Pravasi Vitthal as all three Idols are wearing chappals which the locals believe are the Kolhapuri Chappals.

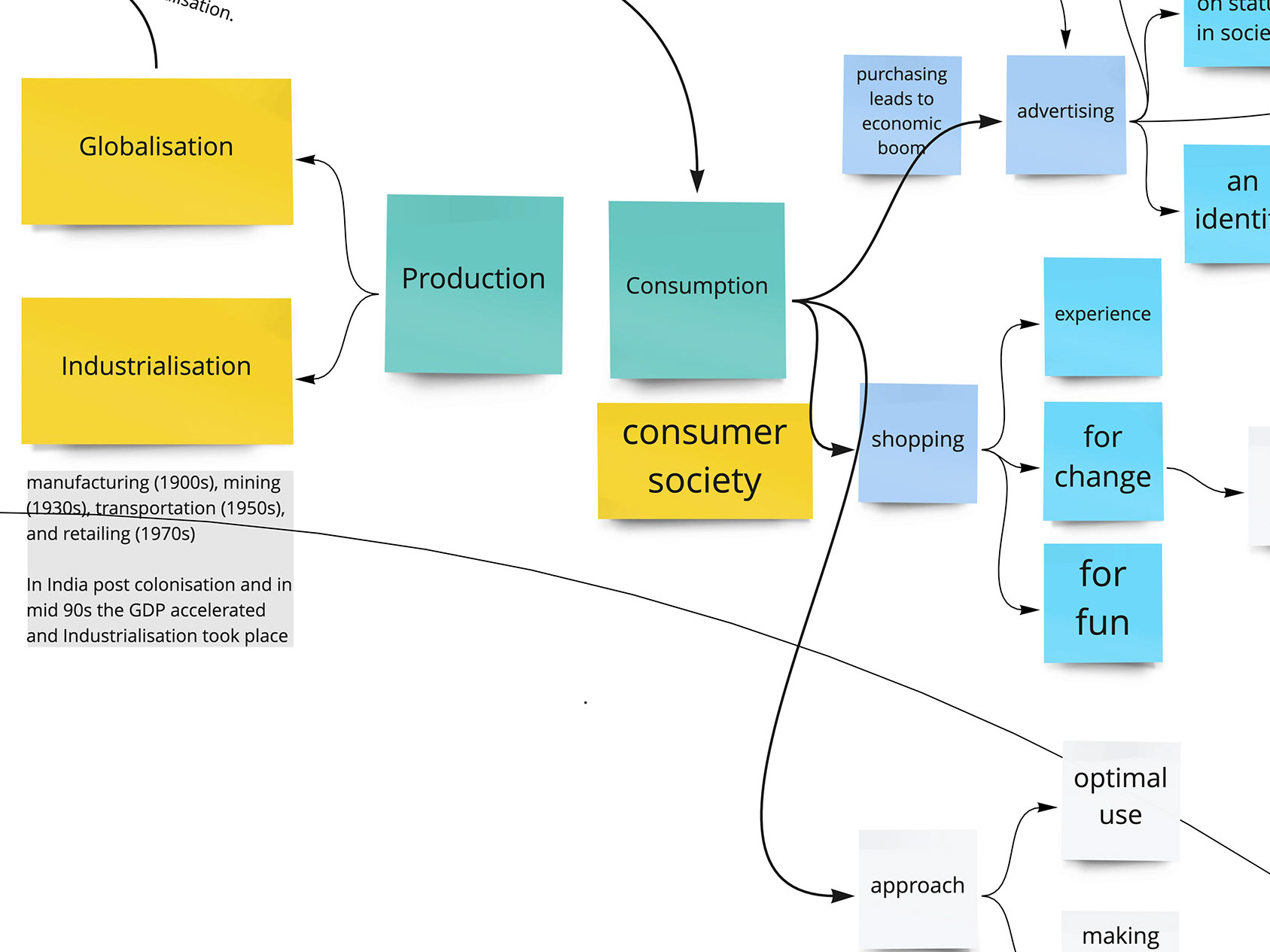

Bara Balutedar System

12 Balutedar system is a hereditary village servant system of twelve trades used in some regions in India, specially in Maharashtra during Shivaji Maharaja’s time.

• Sunar (goldsmith)

• Gurav (temple servant)

• Nhawi (barber)

• Parit (washers)

• Kumbhar (potter)

• Sutar (carpenters)

• Lohar (blacksmith)

• Chambhar (cobblers)

• Dhor (leather tanning)

• Koli (water carrier)

• Chougula

• Mang and Mahar (village watchman, messenger, sweeper)

I tracked down the making of Kolhapuri Chappal in Kolhapur. But during research I came to know that the traditional way of making the chappals is not done in Kolhapur anymore. But now they are stitched at Khadaklath, Karnataka.

Then after tracking down the main source of chappal - the Leather I found that this city had tanneries which are now closed. The leather tanning process was practiced in Kolhapur city.

The Dhor, is a caste in India. Who is traditionally a community associated with tanning leather,

As the tanning process stinks the Dhor community is located in the outskirts of the city. Today due to urban expansion the whole community who was based in the outskirts of the city of Kolhapur had to stop their traditional practices.

I met a person who was a senior in the Dhor community and he gave me the contact of Mr. Arun Kadam owner of a tanning factory.

Kadam family is doing this practice from four generations now. Their great grandfather started as a worker in the tanning factory in Kolhapur. And after a few years he started his own factory in Nipani, Karnataka.

Nipani, Karnataka

In Nipani, there are many leather tanning factories and are practicing the traditional way of tanning. The community is located in the outskirts of the village as this process stinks.

The buffalo farming is done in Hattargi and hide is bought from there.

Earlier leather tanning was done from hides of cows, bulls, buffalos. Today only Buffalo skin tanning is done. Buffalo was farmed and killed and skin and the meat was sold differently.

There are two types of leather tanning in Nipani. Natural and chemical leather tanning. The natural tanning takes 15-20 days for one cycle. Whereas the chemical leather takes 4 days. The chemical tanned leather is also called as Madras Leather.

Temple near the community space.

Society

Traditionally, the world-famous chappals are prepared by some of the Scheduled Caste communities — Chambhar, Dhor and Mahar-Maang.

Carcasses are picked by the Mahar-Maangs and handed over to the Dhors for the month-long processing, during which hide is treated with dye from the hirda and babul plants. Finally, the Chambhars make the chappals, distinguished by their ear-flaps, tassels, patterning, stitching.

Dhor samaj has two types of communities present today in Maharashtra. One that is Rajputi Dhor samaj and other one is Maratha Dhor samaj.

Festival

Dhor community in this village worship Mahadev (Lord Shiva). Mahashivratri is their main festival.

They also celebrate Murgubai Yaatra also known as Nav Paani Yaatra. Nav Paani Yatra means new water. So when it starts raining after summer and the river starts flowing they celebrate this festival. It begins just before Sharvan (first month in the lunar calendar).

They offer a sheep and make Ambil (a sour dal) for the Goddess.

Leather Tanning process

Leather Tanning is a process which is not seasonal or does not have a break throughout the year.

The process that I was able to document was a completely natural leather tanning process. This process involves the activities like obtaining the skin, dehairing, soaking, scrubbing, tying, draining, cutting, stitching, filling and lots more.

The skin is first kept in salt for a day to remove the moisture and they apply rock salt on the hairy side of the skin.Later to remove the hair they dip the skin in lime water. This causes the hair to loosen up. And let it soak in lime water for the next 2 days.

Then removes it and let it soak again in the lime water. They follow this process for the next 10 days.

Community

There is a hierarchy in this community who does the work of scraping the hair off and one that does the rest of the work. Once the hair is removed they turn the skin and remove the fats from it. After that they cut the skin in two parts (a horizontal cut is given from buffalo’s belly).

The people who do this task comes from a particular community. The place where they scrape the hair is called Khatiya.

Once the hair is removed they turn the skin and remove the fats from it. The skin is then dipped in a taaki (water tank). In this taaki the ratio of Hirda and babul is 1:1 and the mixture is called Ekranga.

In Ekranga, Hirda and Babul in this is crushed to powder and poured in water. Here the skin is kept there for 2 days.

They use their legs to stir the water in the tank.

After that they dip the skin in Duranga. In Duranga, the hirda and babul is crushed in bigger pieces and mixed in taaki.

Then they keep the skin for the next 2 days. In this process the skin colour changes. The colour change happens because of Hirda.

They keep removing the hide once in a day and keep it outside in sun. Let it out for 5 mins and they put it back in the takki.

After that they remove it from taaki and wring the hide. And let it dry for next 15 mins.

They use hirda and babli to tan the leather. Hirda and Babul are sourced from Junnar, Nasik. They buy it yearly 5-6 tons each.

In earlier days, women used to crush the Hirda and Babul and stitch the leather for tanning.

After that they drain the water out from skin. And stitch the skin with the help of a grass that grows on the edges of farms. The grass is called Fada and they buy it from Maang community people from Kolhapur. They stitch the leather by this grass and with the help of two tools Raapi and Aari.

Faada is a grass whose one end is hard and they sharpen it and use it as a needle.

They use this grass in particular because the tanning process the leather sack gets heavy and a lot of water is used in the process. The wear and tear of any other rope does not help the leather sack to be tight and lift such a heavy load.

They stitch the skin and put Hirda and Babul in bigger pieces along with that they also pour water in it and tie a knot with a strip of leather. The place where they hand it is called Dukkan. For 8 tanks they need 2 Dukaan.

They remove the Hirda and Babul and untie the sack. They dip the hide in the water beneath it. They keep the hide in the sun till it dries completely.

Tools used to carry out the whole tanning process.

A. Sip - To remove the hair by scraping.

B. Raapa - To remove fats after removing hair.

C. Raapi - To tear the hide while stitching into sacks.

D. Aari - To makes hole while stitching.

E. & F. - Stone - To sharpen tools.

All of these tools are made without welding or any new method. They are metal blades with wooden handle where rubber is wrapped at the joinery.

A. Water source for the Khatiya (hair scraping place)

B. Water source for house old activities like washing clothes, utensils, hands, etc.

C. Water stored to wash their hands in middle of the work.

D. Lime water tank

E. Lime water tank

F. Platform to remove hair

G. Dukkan

1-8. Water tanks

No part of any project displayed herewith may be reproduced, distributed or transmitted in any form or by any means, including photocopying, recording, or other electronic or mechanical methods, without the prior written permission of the publisher.